化学反应器种类繁多常见的化学反应器类型

它们有哪些?

首先,需要明确的是,化学反应器是现代化工生产中不可或缺的设备。它们用于控制和执行各种化学过程,从简单的混合到复杂的催化剂作用。不同类型的反应器能够适应不同的生产需求和操作条件。

为什么需要这些不同的类型?

每一种反应器都有其特定的设计理念和应用领域。选择合适的反应器对于提高产品质量、优化生产效率、降低成本以及保证安全操作至关重要。从而,我们可以看到,每种类型的反应器都有一套独特的优势。

如何分类这些反

作器?

根据其工作原理、结构设计以及使用目的,化学反应器可以分为几个主要类别:

1. 混合塔

混

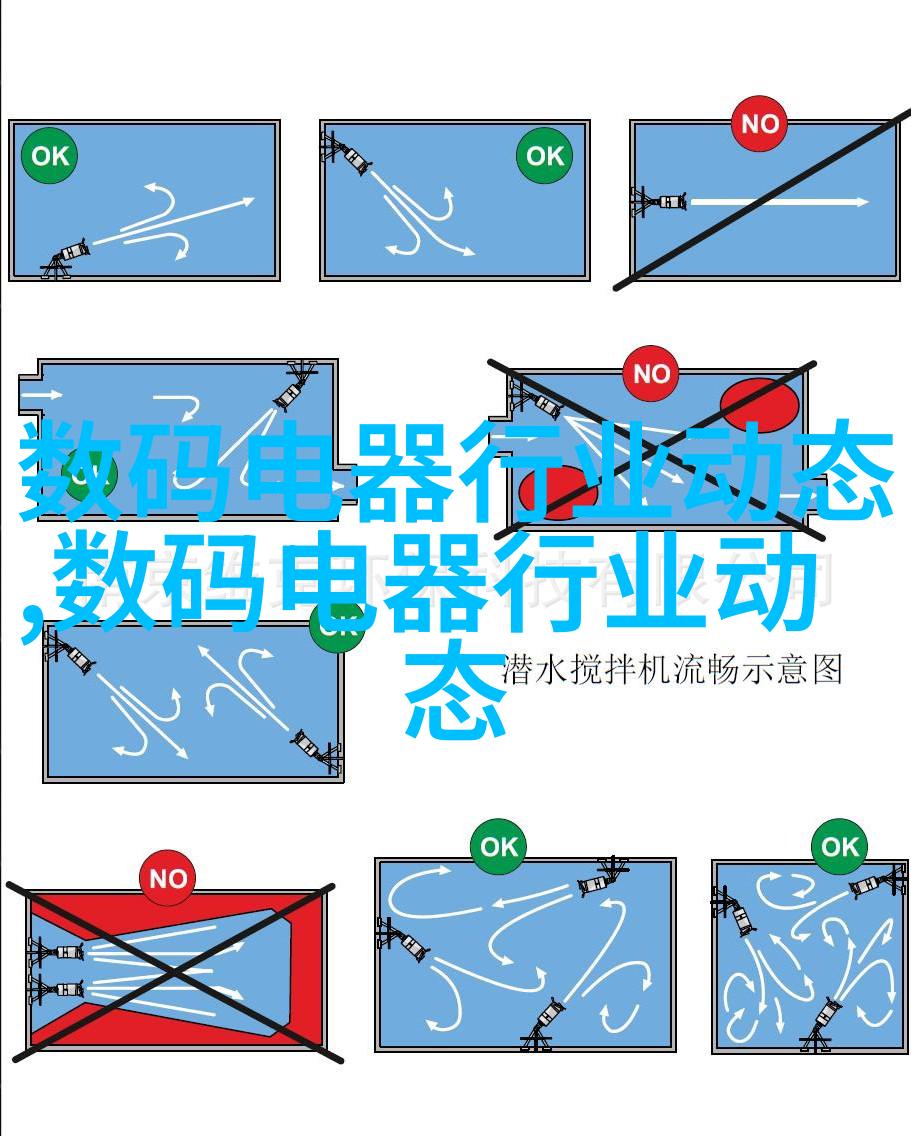

别塔又称为静置沉淀塔,它通常用于液相或气相中的物质进行混合。在这一过程中,可以实现物质间充分搅拌以促进溶解、发酵或者其他所需的手段。此外,还能通过层流或循环流动方式来实现某些物质之间有效地接触与交换,这在工业上非常关键,比如制药行业中的固体颗粒与溶剂混合。

2. 反应釜

反

应釜也被称作加热罐,是一种多功能容纳空间,可以承受高压高温环境。在这个环境下,进行各种强烈氧化还原、蒸汽还原等强烈化学变化十分普遍。这一设备对于大规模制造精细化工品来说无疑是一个宝贵资源,因为它能够同时提供必要的大气密封性、高温加热能力及良好的搅拌效果,使得实验室试验直接转移到工业规模上。

3. 熔融回收炉

熔融回收炉是一种特殊设计用途专门处理含有金属粉末等难以处理废弃材料的一种设备。在这个过程中,不仅能将废旧金属彻底熔炼成纯净金属,还能有效减少对自然资源造成额外消耗,这对于保护地球环境具有极大的意义,同时也节省了大量经济资源。

怎样选择最合适的反

作器?

在实际应用中,由于各种原因,如成本预算限制、技术要求严格或者是时间紧迫的情况下,如何快速准确地选出最佳方案就显得尤为重要了。在此情况下,可考虑以下几点因素:① 设计性能;② 过程稳定性;③ 能源消耗;④ 维护保养成本;⑤ 生产效率等。如果所有这些参数都得到妥善考虑,并且做好详尽研究后,就很可能找到一个既符合项目要求又可行性的解决方案来满足我们的需求。

chemical reactor types are numerous, and each type has its own unique advantages and applications. They can be broadly categorized into several main categories based on their working principles, structural designs, and intended uses.

Why do we need these different types of chemical reactors? Each type of reactor has its own set of advantages that make it suitable for specific production requirements and operating conditions. Choosing the right reactor is crucial for ensuring product quality, optimizing production efficiency, reducing costs, and ensuring safe operation.

How to classify these reactors? Chemical reactors can be classified into several major categories based on their design features and application purposes:

Mixing tanks: These are also known as settling tanks or sedimentation towers used for mixing materials in liquid or gas phases to promote dissolution, fermentation or other desired processes in industries such as pharmaceuticals where solid particles must interact with solvents.

Reaction kettles: Also known as heat exchangers or reaction vessels they provide high-pressure-high-temperature environments necessary for strong oxidation-reduction reactions like steam reduction etc., which are commonly used in large-scale manufacturing of fine chemicals making them a valuable resource by providing necessary atmospheric sealing capabilities at high temperatures along with good mixing effects allowing experiments conducted in laboratories to be directly scaled up industrially.

Melting furnace: This is a specialized device designed specifically for processing waste materials containing metal powders using various methods like smelting refining recycling etc., not only melting but also purifying metals effectively reducing additional consumption on natural resources while saving substantial economic resources simultaneously contributing significantly towards environmental protection.

What considerations should be made when choosing the best reactor? When selecting the most appropriate solution under time constraints budget limitations strict technical requirements urgency situations consider factors such as design performance process stability energy consumption maintenance cost production efficiency if all parameters receive proper consideration after thorough research it's likely to find a feasible solution meeting project demands.